REGO-FIX Switzerland

Obermattweg 60

4456 Tenniken

+41 61 976 14 66

+41 61 976 14 14

REGO-FIX – A Swiss success story

Its long-term business success is based on promoting employees and enabling them to shape the future together in a fast-paced environment. REGO-FIX has a great mutual respect and maintains cross-cultural cooperation with the aim of developing innovative toolholding solutions together. Ongoing investments in research and development also lead to constantly new products and ensure a competitive product range. The trademark with the ”triangle” is steadily gaining worldwide recognition: Today it is known throughout the industry and stands as a quality label for reliable and innovative products made in Switzerland!

“We engineer and manufacture all our products at our headquarters. Here, from Tenniken, we deliver our innovative Swiss-made tool clamping systems worldwide.”

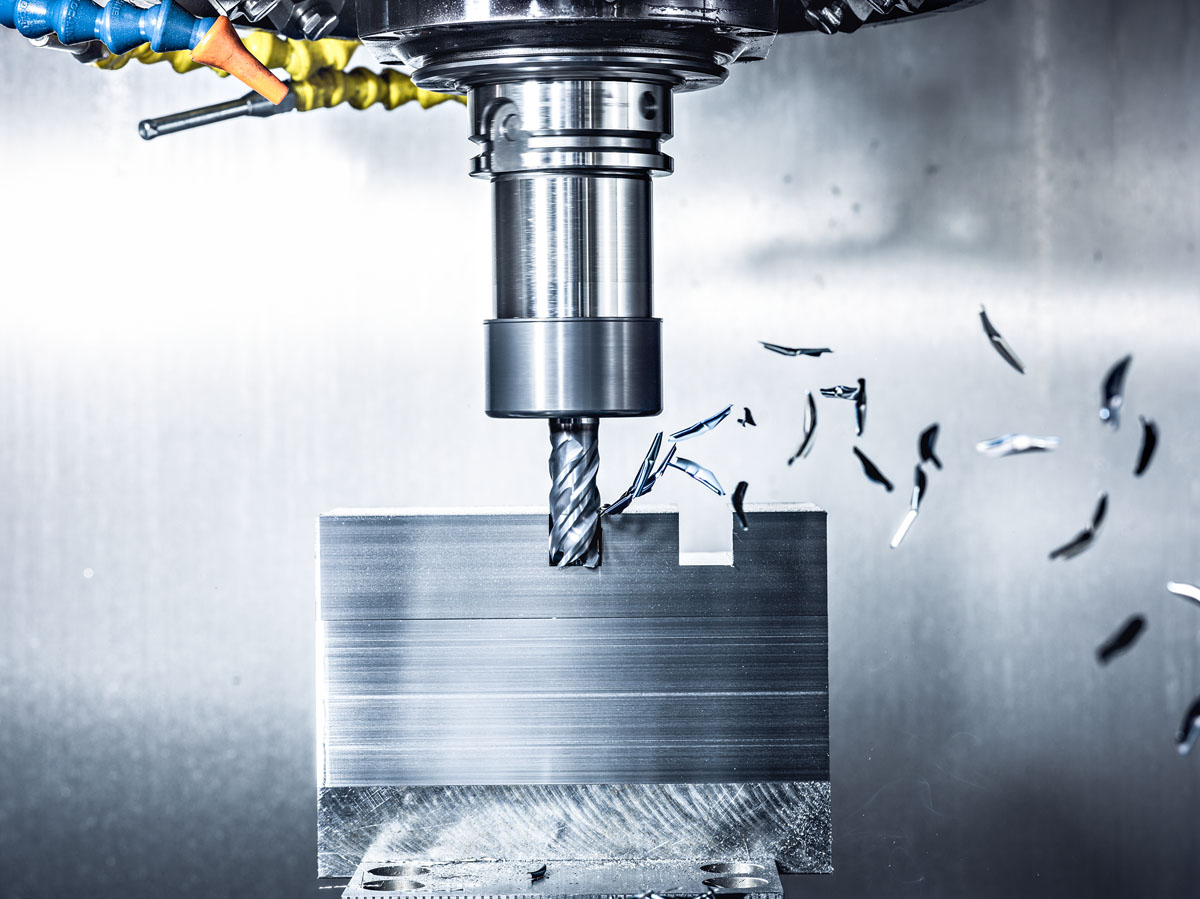

The powRgrip® System provides excellent runout, high vibration dampening as well as easy and secure handling for demanding high-speed milling and drilling applications.

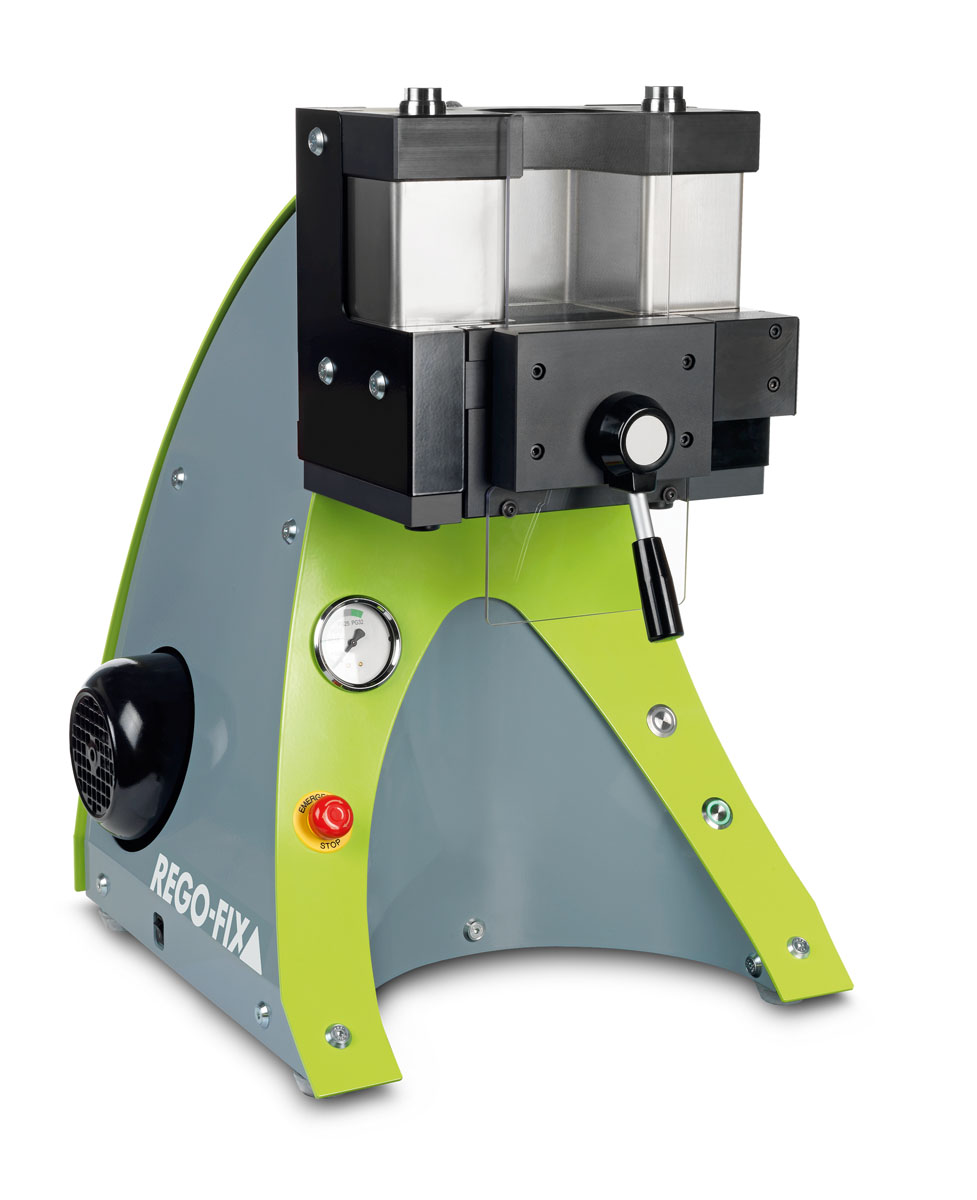

Easy heat-free tool clamping

The innovative technological accomplishment is reflected in the uniqueness of the tool clamping procedure in a demanding high-precision environment, as well as the persistence of the clamped toolholder. Thanks to the unique clamping method of the clamping unit PGU 9500, the clamped tools can be used in production quickly and safely.

The very precise concentricity and optimum vibration dampening of powRgrip® increase tool life and save time and money. The advanced technology not only increases the work safety for the user, but also reflects our ecological thinking, which manifests itself – among other things – through low energy consumption during the clamping process.

Key advantages

- Total system runout TIR ≤ 3 µm at 3 × D

- Tool ready for use in 8 seconds with the PGU 9500

- Excellent vibration dampening thanks to two interfering surfaces