Starrag AG

Seebleichestrasse 61

CH-9404 Rorschacherberg

+41 71 858 81 11

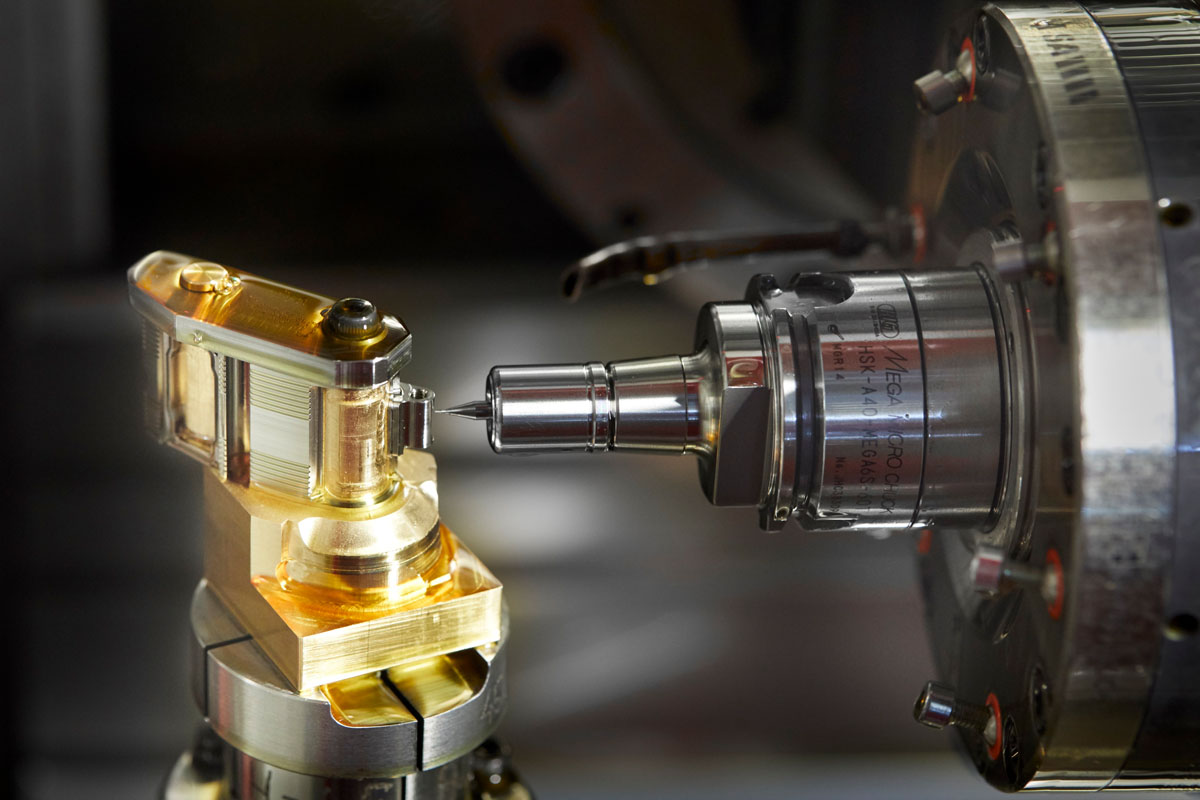

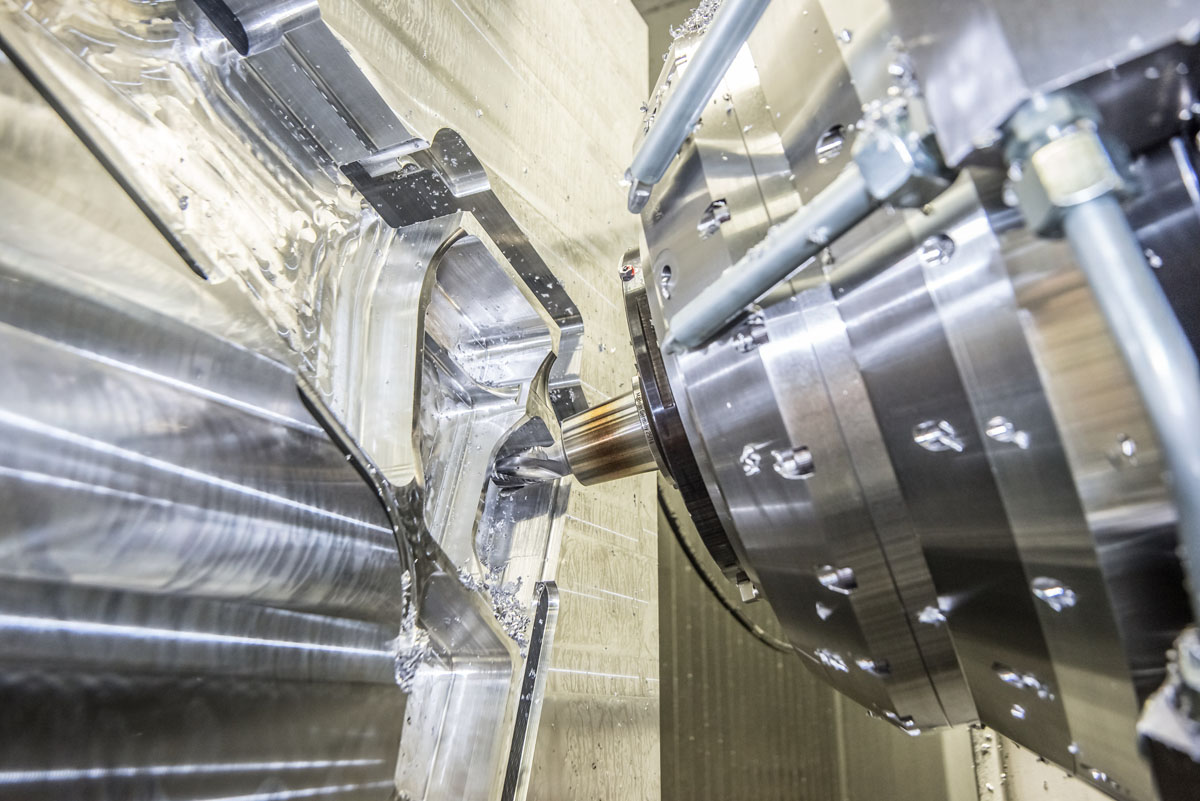

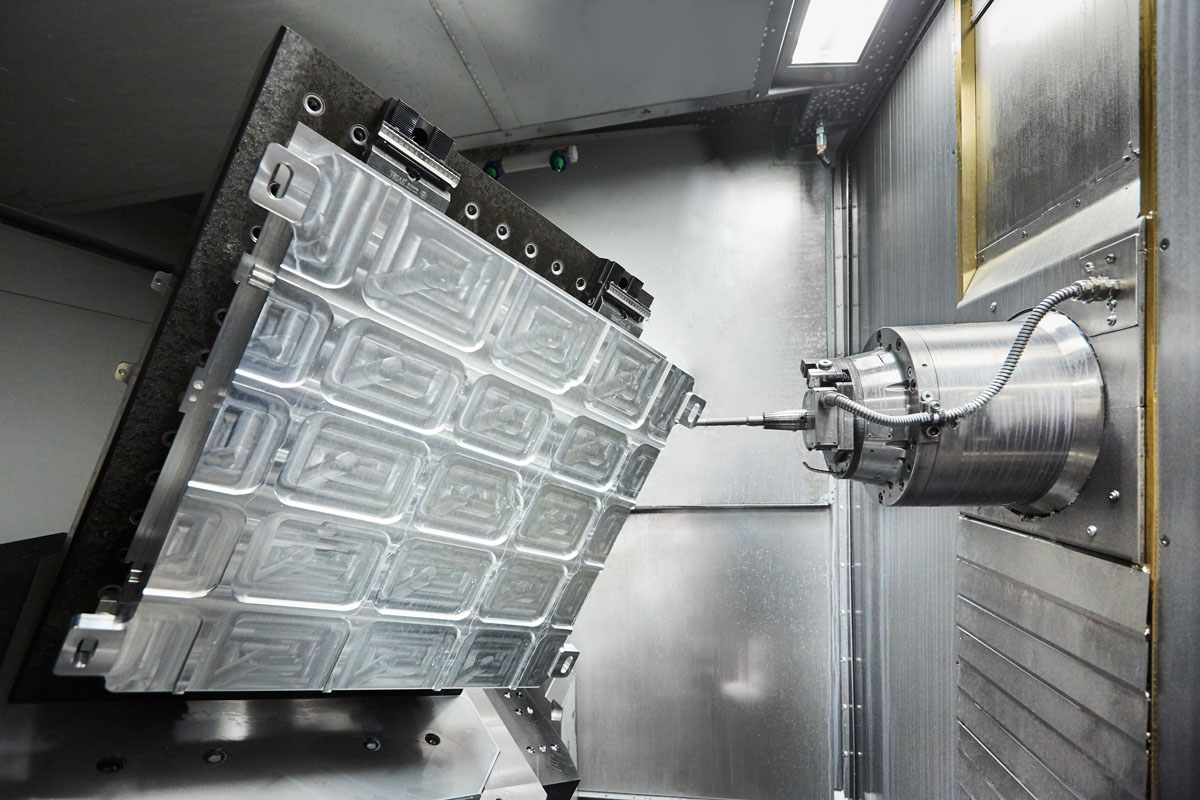

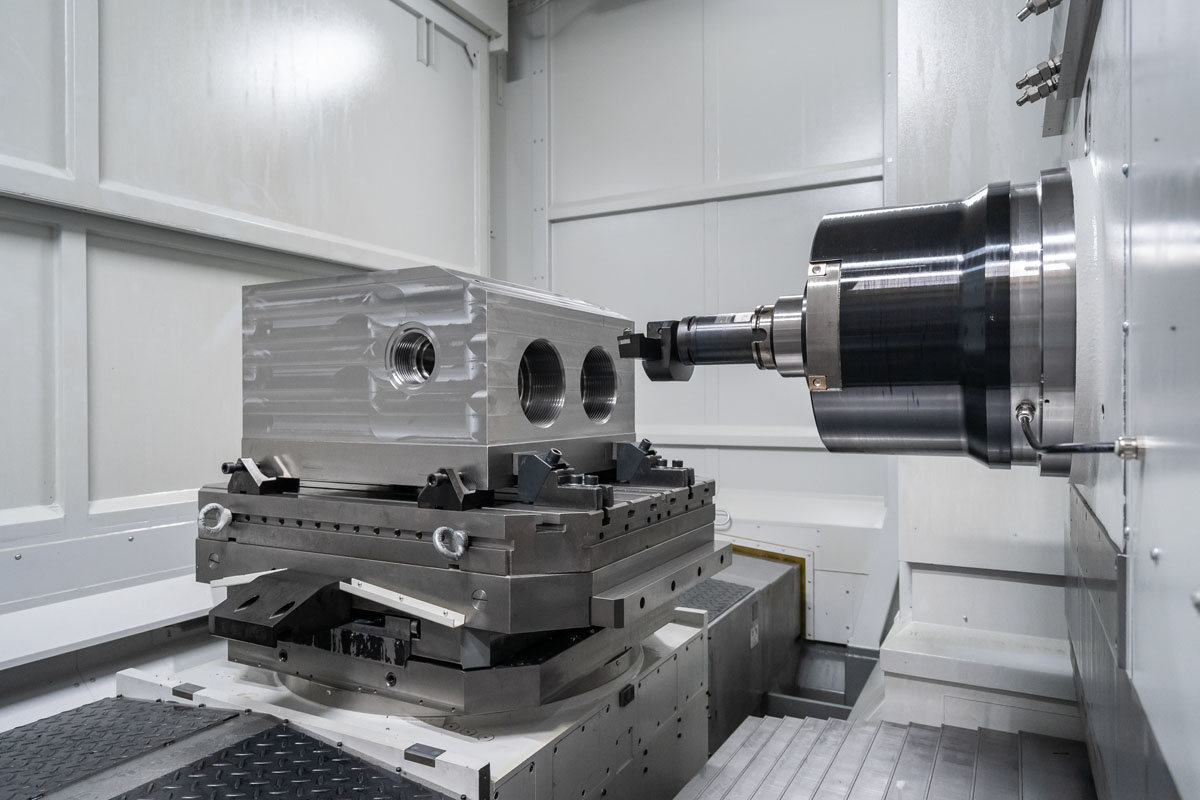

High-precision machine tools for greater productivity

Starrag Group is a global technology leader in manufacturing high-precision machine tools for milling, turning, boring and grinding workpieces of metallic, composite and ceramic materials. Principle customers are internationally active companies in the Aerospace, Energy, Transportation and Industrial sectors (Industrial Components, Luxury Goods, MedTech). In addition to its portfolio of machine tools, Starrag Group provides integrated technology and maintenance services that significantly enhance customer quality and productivity.

The umbrella brand Starrag unites the product ranges Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP, Starrag, TTL and WMW. Headquartered in Rorschach/Switzerland, the Starrag Group operates manufacturing plants in Switzerland, Germany, France, the UK and India and has established a network of sales and services subsidiaries in the most important customer countries.

The shares of Starrag Group Holding AG are listed on the SIX Swiss Exchange.