MOTOREX AG

Bern-Zürich-Strasse 31

4901 Langenthal

+41 62 919 75 75

MOTOREX INDUSTRIAL LINE

Our customers are at the heart of all our thoughts and actions.

In the course of MOTOREX’s over 100 years in operation, our high level of innovation coupled with our entrepreneurial vision have been the key to our success as a specialist in industrial lubricants. Building on this expertise, yet another new innovation has emerged from our ingenious development department: FLUIDLYNX by MOTOREX, professional fluid management for the industrial sector.

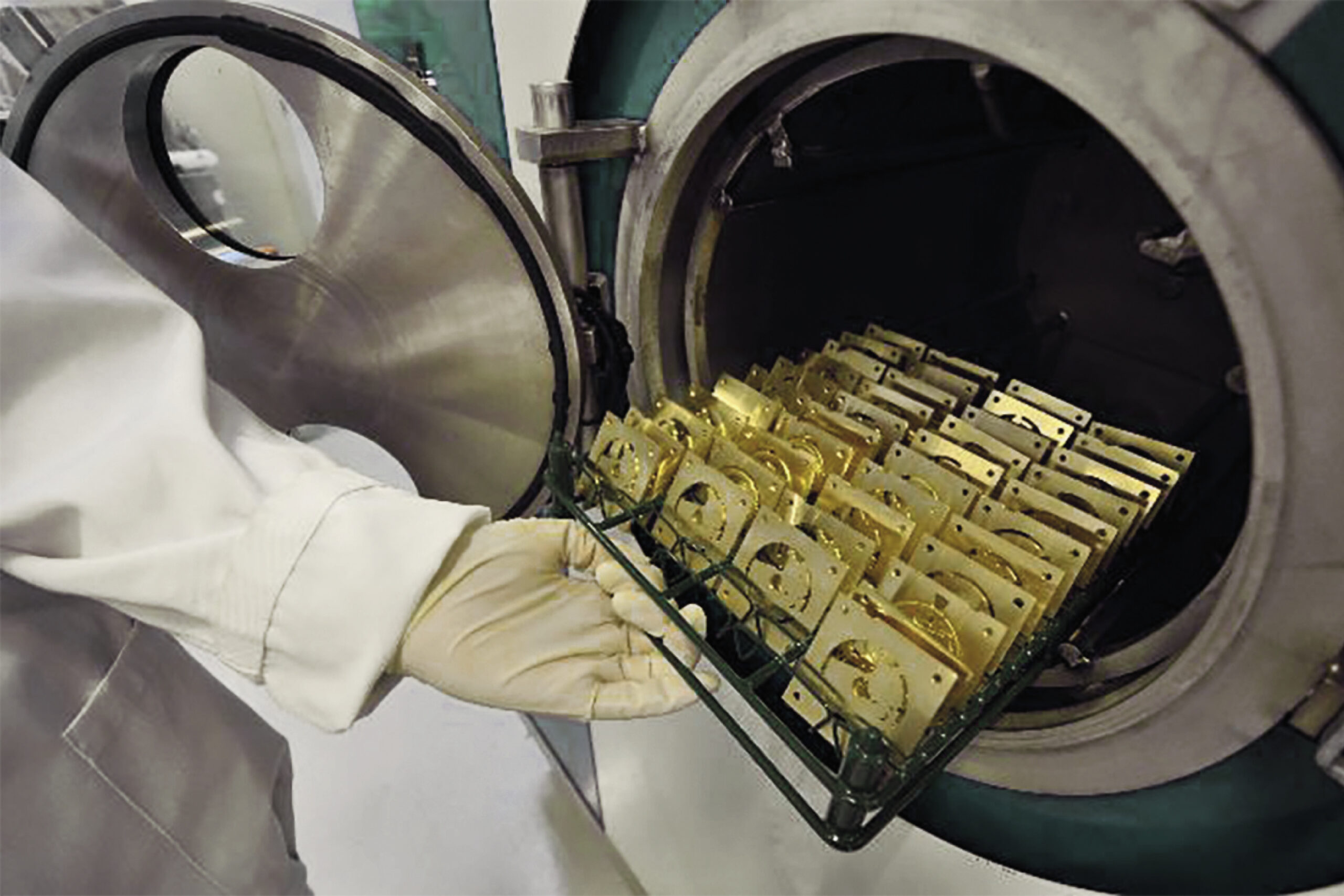

The MOTOREX INDUSTRIAL LINE is specifically tailored for the following industrial sectors:

- medical

- electronics/semiconductors

- watches/jewellery

- automotive

- general machining

- aerospace

STAY SWISS – Swiss ingenuity – over a century of innovation at our site in Switzerland.

Automated fluid management with FLUIDLYNX by MOTOREX

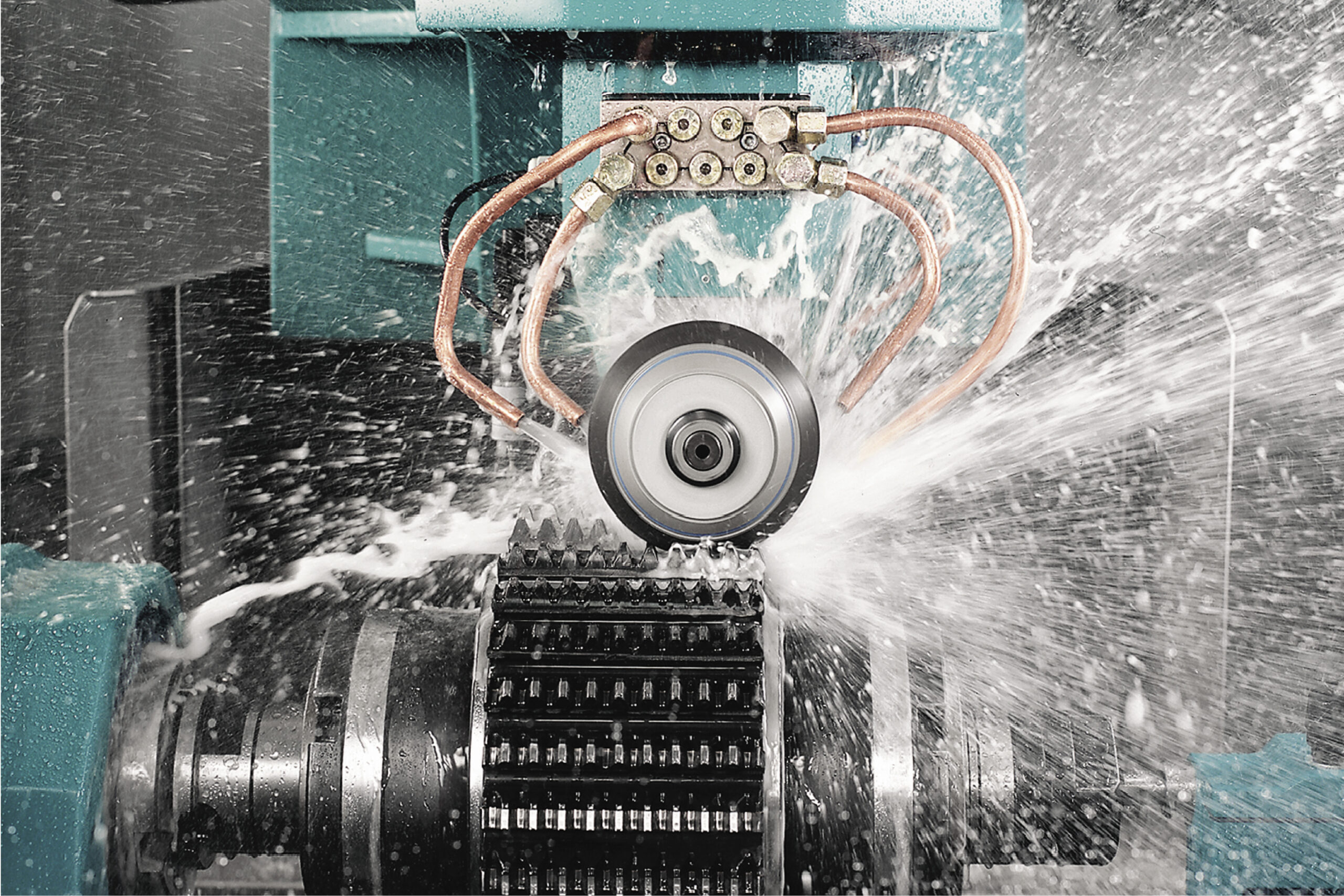

FLUIDLYNX allows water-miscible coolants, cutting oils and grinding oils to be measured, regulated and traced reliably 24/7 for individual production machines or throughout the entire production process. The comprehensive solution can be scaled or expanded to include any future production systems. By using FLUIDLYNX by MOTOREX, you will protect your production equipment and workpieces, ensure a high level of process security and extend the service life of water-miscible coolants, cutting oils and grinding oils. It’s a smart way to conserve resources and help the environment. Your employees will also benefit as they will be able to concentrate on their core areas of expertise and reduce contact with the fluids, which in turn will protect their health.

Find out more about the equipment involved in the FLUIDLYNX comprehensive solution for automated fluid management:

FLUIDLYNX, COOLANTLYNX, NEATBOX and EASY MONITORING

An overview of the MOTOREX range for the industrial sector:

- FLUIDLYNX automated fluid management by MOTOREX

- water-miscible coolants

- cutting oils

- grinding fluids

- spindle operating fluids

- EDM fluids

- forming oils

- corrosion inhibitors

- cleaning agents

- process auxiliaries