Ultimate versatility: Affolter unveils gear hobbing machine AF160

Press Release, April 8th 2021, Malleray, Switzerland, Affolter Group

Ultimate versatility: Affolter unveils gear hobbing machine AF160

– The Swiss family enterprise Affolter Group (www.affoltergroup.ch), a world technology leader in gear hobbing, introduces its most versatile machine to date: the AF160.

– The 8-axis CNC gear hobbing machine handles a broad range of applications to produce different kind of gears and worm screws with a module of up to 2mm. It is ideal for manufacturers in the automotive, aerospace, aircraft, gearbox, medical and robotics industries.

– The state-of-the-art digital CNC Control Pegasus is user-friendly, ensures extremely fast regulation and integrates IoT. Various automation solutions facilitate flexible manufacturing of small series or high volumes with an autonomy of 12 to 24 hours.

Precision, productivity, flexibility

Switzerland (April 8, 2021) – Precision, productivity, flexibility: The experts of the Swiss family enterprise Affolter Group (www.affoltergroup.ch), a world technology leader in high-precision gear hobbing solutions, introduce their newest machine: The AF160 is the most versatile Affolter gear hobbing machine to date. “The AF160 is designed for high precision manufacturers that need versatility and maximum efficiency,” explains Vincent Affolter, Managing Director of Affolter Group. “With eight axes, a state-of-the-art digital CNC control, a variety of automation solutions and a maximum module of 2mm, it is ideal for manufacturers in industries such as automotive, aerospace, aircraft, gearbox, medical or robotics.”

The AF160 can process parts with an outside diameter of up to 60mm and a length of 250mm. The machining length is between 110 and 180mm. The eight axes – all of them independent – make the AF160 the most flexible Affolter machine to date. It can produce straight gears, helical gears, straight bevel gears, face gears, straight or helical crowned gears, worm screws, worm wheels, cylkro gears, and internal gears. Power skiving, the milling of worms and shafts, as well as chamfering is possible, too. Vincent Affolter: “The AF160 enables manufacturers to produce an impressive variety of high precision gears, worm screws and worm wheels on the same, compact machine.” The footprint of the machine is only 4m². Including the loader AF72 it is a little more than 6m².

Not only a machine. A solution!

With the AF160, Affolter does not only introduce a groundbreaking new gear cutting machine. “We think of it as a solution, not a machine – a solution that meets the needs of our customers. Thanks to the new CNC Control, various automation systems and peripherals, and the versatility of the AF160, we can offer maximum productivity for high-precision manufacturers in a very broad range of applications,” emphasizes Vincent Affolter.

Intuitive CNC Control

The engineers of Affolter Group cooperated with Beckhoff Automation to launch the brand-new CNC Control Pegasus. The high processing power ensures extremely fast regulation. “It controls all machine axes as well as a multitude of peripherals for various options and automations,” says Mr. Affolter. Programming is simple, intuitive, and user-friendly with a 19-inch touch screen. The new CNC Control integrates IoT. Data can be shared on the cloud, streamlining after-sales service and preventive maintenance, and therefore minimizing downtimes. Software updates can be done remotely.

Automation boosts productivity

Depending on the application and production processes, manufacturers need automation solutions to facilitate an autonomous operation for 12 to 24 hours. Affolter provides a range of such automation solutions: The universal multi-axes part loading and unloading system AF72 was especially designed for the AF160. It features a double gripper system for parallel loading and unloading and offers different methods of feeding based on the volume, product, and application. The AF160 can also be equipped with the deburring unit AF54, integrating the deburring process into the gear production. Different clamping systems provide for added versatility. Customizable coolant systems and chip extraction conveyors are available as well.

AF160 Technical Characteristics

– 8 axis CNC

– Max. module 2.00 m / 12.7 DP

– Max. cutting length 110-180 mm / 4.33-7.08 in.

– Max. part diameter 60 mm / 2.36 in.

– Spindle rotation B 9’000-16’000 rpm

– Spindle rotation C-C’ 5’000-12’000 rpm

– Dimensions LxWxH 1’500×2’010×2’650mm

– Weight 3’900 kg / 8.598 lb

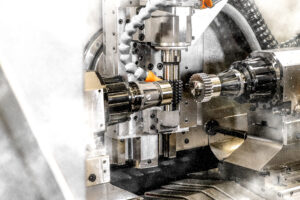

Picture legend: Eight

independent axes make the

AF160 the most versatile

Affolter gear hobbing center

on the market. (Picture

source: Affolter Group SA)

Picture legend: The flexible

AF160, with a maximum

module of 2mm, is ideal for

manufacturers in various

industries from automotive

and aerospace to medical

and robotics. (Picture

source: Affolter Group SA)

Picture legend: The new

CNC Control Pegasus

integrates IoT, making

preventive maintenance

possible and minimizing

downtimes. (Picture

source: Affolter Group SA)

Affolter Group is a family enterprise

About Affolter Group: Tradition meets innovation: The Affolter Group is a family

enterprise and world technology leader in high-precision gear hobbing solution with more

than 160 employees around the globe. The highly specialized company was founded in

1919 by Louis Affolter in Malleray, Switzerland. The more than 100-year history of the

Affolter Group was filled with technological innovations. Today, the fourth generation

leads the family enterprise. The Affolter Group operates worldwide with a broad network

of distributors. For more information, please visit: www.affoltergroup.ch

Follow us!

Facebook | LinkedIn | Instagram | YouTube

Hagen PR

www.hagenpr.com

In case of publication please send a copy to Hagen PR, Klostergasse 2-26, 6850 Dornbirn,

Austria, or as a PDF to news@hagenpr.com