LONG PARTS ON MULTISPINDLE TURNING MACHINES

Working within the limits of the material

One of the features of bar turning machines is their ability to produce long parts that generally exceed the limit of 2.5 times the diameter. This is a key feature and this feat is made possible thanks to the guide bush, a central component along with the machine spindle used to drive the bar.

The bar turning principle is that the tool is fixed and the bar moves along the Z-axis, in contrast to fixed headstock turning machines where the tools are mobile.

This principle is also found on multispindle machines, in fact, on these machines, the bar remains fixed after it is fed into position. In 2011, with the MultiSwiss 6×14 machine, Tornos launched an innovative concept – a mobile spindle specially designed to separate the guides, thereby making the elements rigid.

All MultiSwiss machines are equipped with spindles with high-power synchronous motors ensuring the machine offers impressive dynamics, the acceleration times are very short (0-8000 rpm in under a second on a MultiSwiss 6×16). In addition to its own C-axis, each spindle has its own Z-axis, guided by hydro- static bearings.

This enhances vibration damping, extends the service life of the tools and improves the machined surface finishes. MultiSwiss machines are very quiet – thanks to the torque motor driving the barrel, along with the motor spindles – which makes them even safer and more comfortable for operators to use. However, even with this innovative concept, the laws of physics remain the same when it comes to the material’s flexibility.

A new possibility for long parts

Although single-spindle machines use guide bush technology to support the part, this is not the case for the MultiSwiss machine, where the support solution was favoured. Tornos gave a great deal of thought to using a guide bush that could be fitted on the barrel, but this solution posed several problems relating to chip removal and especially in terms of machine setup and adjustments. MultiSwiss machines now offer excellent accessibility as well as being quick to set up. The chip removal is outstanding and the embedded hydrostatic technology in the machine spindle gives impressive results and minimises tool wear, even with the most exotic materials.

The addition of a guide bush compromised the machine’s key features and a more conventional solution was also conceived with supports that could be fitted in the machining area. This solution guaran- tees excellent repeatability and ensures a quick setup without compromising chip removal.

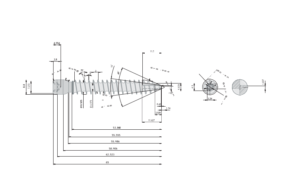

The system was unveiled during the EMO trade show in 2021 on a MultiSwiss 8×26 machine that was pro- ducing a 65 mm long poly-axial medical screw with a head diameter of 8.8 mm. The machining operation was performed with a double feed. The first feed was used to perform the initial bar turning and self-tapping milling operations. The second feed occurred in position 2, then the part was held in positions 3, 4 and 5 thanks to a tailstock. The tailstock relies on a modular system which enables the support to easily adapt to the type of part.

This option is only available ex-works.

To find out more, please contact your nearest Tornos representative.

Tornos SA

Industrielle 111

CH-2740 Moutier Switzerland

Tel. +41 32 494 44 44

tornos.com