Innovative ideas turned into innovative machines

A Report by pl Lehmann AG

Swiss Rotary Table Technology

Two-axis CNC rotary table from pL LEHMANN complements a

Mazak machining center for accurate, flexible and profitable machining.

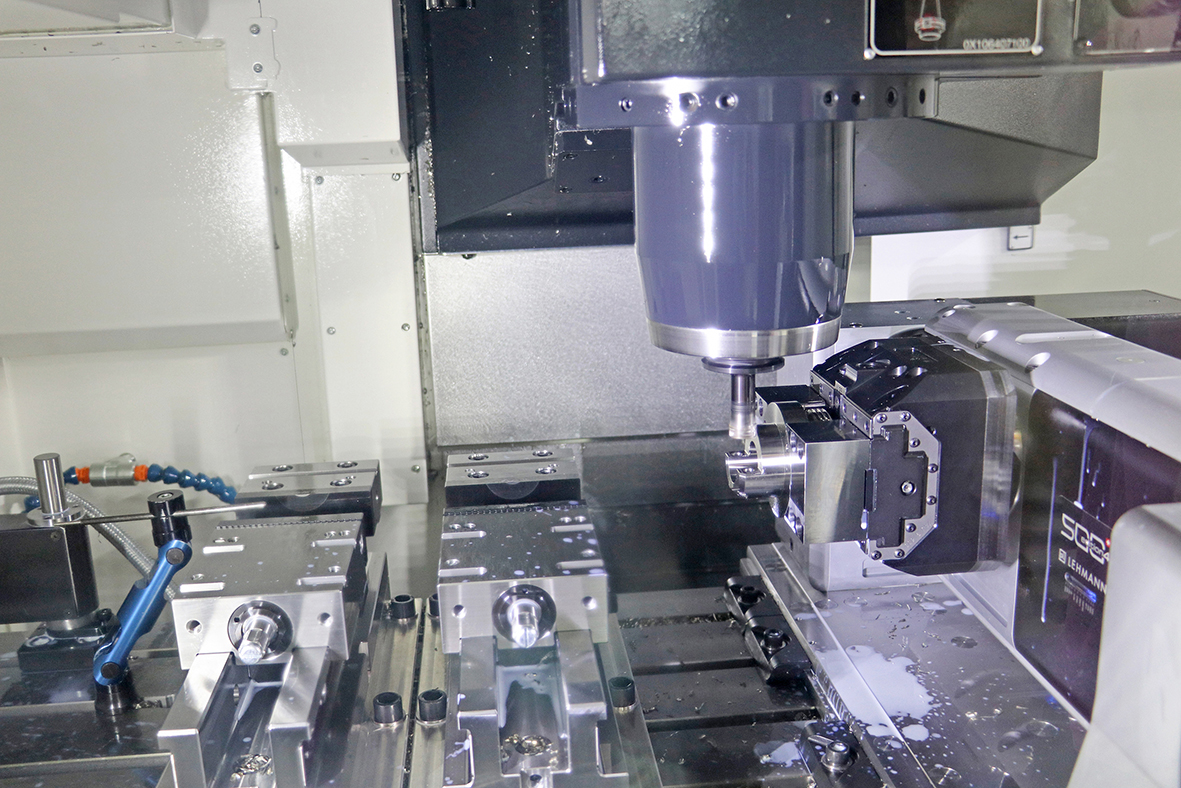

LOESCH T-P-L in Darmstadt is a source of ideas as well as a supplier to major machinery manufacturers. In their in-house production facility, complex parts which require a high level of know-how are machined with ultimate accuracy. Here, a Mazak VCN 530C vertical machining center stands out for its particularly high efficiency. Thanks to the addition of a two-axis CNC rotary table from pL LEHMANN, the setup can machine parts on five sides using five axes.

Darmstadt, Frankfurter Landstraße 70 – the address in this residential area does not give a clue to the fact that this is the site of company which counts high-precision machining to its core competences: LOESCH T-P-L mechatronic systems GmbH. Managing director Michael Loesch explains: «We are more than just a metal-cutting service provider. We are best described as an innovative partner of various renowned enterprises, primarily supplying ideas, developments and our own products.»

Loesch emphasizes that his relatively small company with a staff of ten relies on almost 70 years of experience in the development and manufacturing of high-precision mechanical parts and components and that a lot of time and effort is also invested into innovation. The company has been participating in several research projects conducted by universities and major partners from the industry, implementing the insight gained from the projects into market-ready products.

Loesch’s product range covers three main areas: 1. testing equipment for the automotive industry; in particular specific components for engine and brake system test benches; 2. handling devices and components for plasma powder and laser cladding; and 3. measuring and testing equipment for the pharmaceutical, cosmetics and chemical industry. «Our know-how in these areas is extensive, and we not only apply it to the manufacture of parts, but also to their mechatronical requirements», says the managing director, adding: «Of course, metal cutting is a an essential core competence because all complex, important parts are manufactured in-house.»

Mazak dominates production

The company’s ground floor houses six CNC machines – all made by Mazak. «We’ve had close ties with this Japanese tool machine manufacturer since 1979», explains Michael Loesch. «Back then, my father, the founder of our company, ordered the first Mazak lathe. Further lathes and machining centers were added over the years, and we have always happily relied on Mazak’s technical advice, delivery and customer care.»

Naturally, the latest addition to the machine pool, a vertical 3-axis machining center of type VCN 530C, was procured from Mazak as well. However, this unit was then extended by a CNC rotary table combination from pL LEHMANN to facilitate machining along five axes. LOESCH T-P-L decided for this setup for reasons of production efficiency, something that must always be kept in mind even though corporate structures are very flat and efficient. Using five-axis milling and drilling technology, Michael Loesch realizes benefits for many workpieces from across the entire range of customers. «In general, all parts can be manufactured on a 3-axis machine as well. However, this requires special clamping fixtures for angled surfaces and bores – and multi-sided machining always requires the re-clamping of parts in different positions. This costs time and is detrimental to accuracy. From a technical and economic point of view, 5-axis machining is without alternative.»

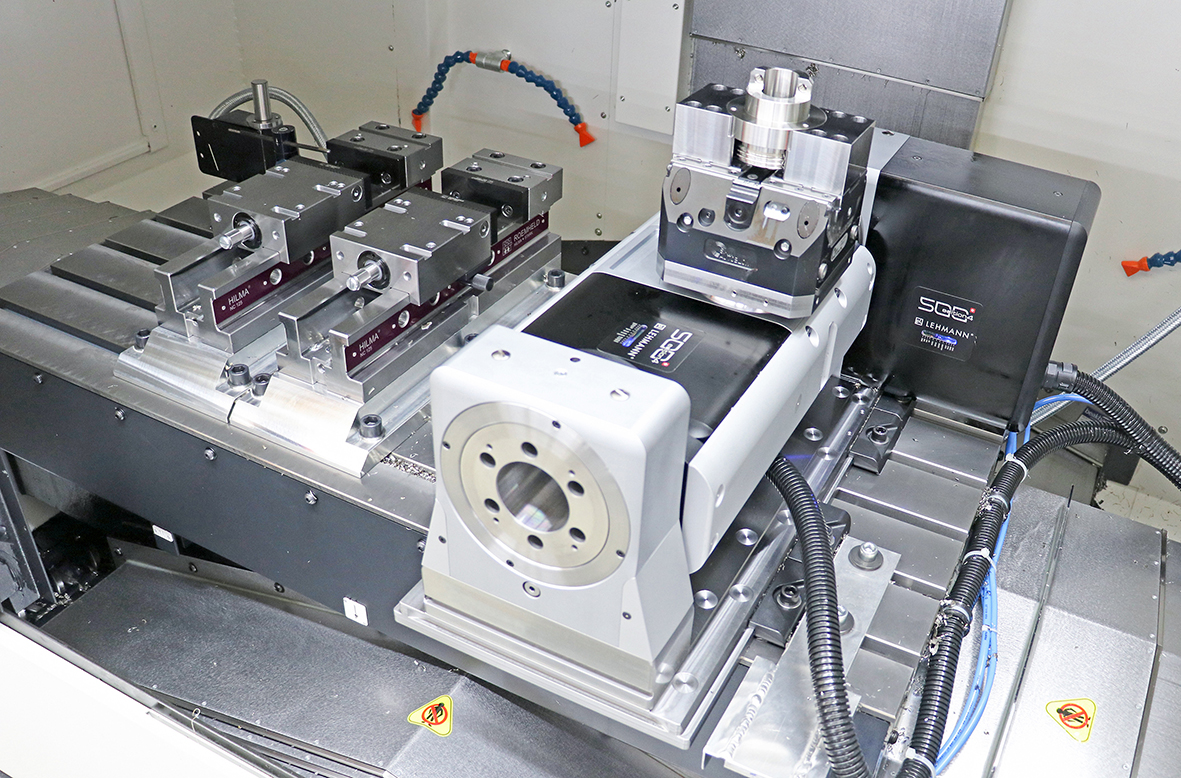

However, a machine originally designed with 5 axes was not an option for Michael Loesch: «Rocker-mounted rotary tables are usually rather small, or we would have had to spend a lot of money for a correspondingly larger machining center.» Such a solution also entails interfering edges which require a raised fixture for the workpiece or at least long tools. Both of these reduce stability, promote vibrations and ultimately reduce precision and machine performance. Moreover, a 3+2-axis solution is less expensive while offering a greater flexibility. «For us, the Mazak VCN extended by the Lehmann rotary/tilting table is the perfect solution. It even leaves enough room to accommodate two more vices on the machine table, thus providing further clamping options for simpler workpieces or the sixth side.»

With the Mazak VCN 530C, Michael Loesch and his team of metal-cutting experts are convinced to have found the vertical machining center (of its range) with the highest productivity. Cycle times are very short thanks to the high feedrate (42 m/min), excellent acceleration/deceleration and quick tool changes (2.8 s). Durable linear roller guides ensure consistent machining accuracy along all axes. The machine was specified with a 40x tool magazine, a 18’000 min-1 high-speed spindle and a Knoll 70 bar high-pressure system, reducing machining times for deep-hole drilling by up to 90%.

To the LOESCH team, the 1300 x 550 mm table was of particular importance as it can fit the CNC rotary table from pL

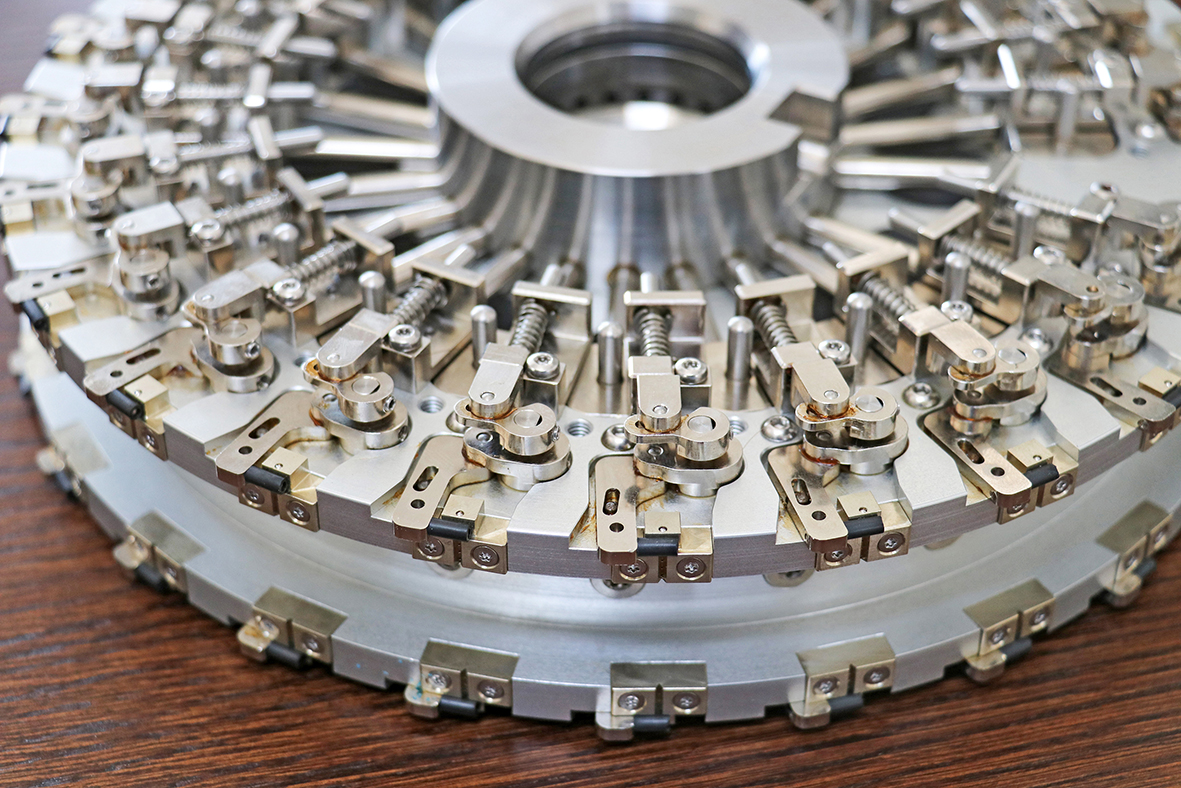

LEHMANN and still provide enough space for two vices of size 125. Supported by the rotary table specialists from Switzerland and German sales and service partner IVO Oesterle, the team selected the two-axis model T1-510520.RR TOP2. «The Swiss quality won us over at the first presentation. With regard to performance and suitability for digitalization and Industry 4.0, we did not consider any of the alternatives.» 3D-CAD data of the CNC rotary table were submitted to the team beforehand, so a matching workspace concept could be worked out in the in-house CAD system.

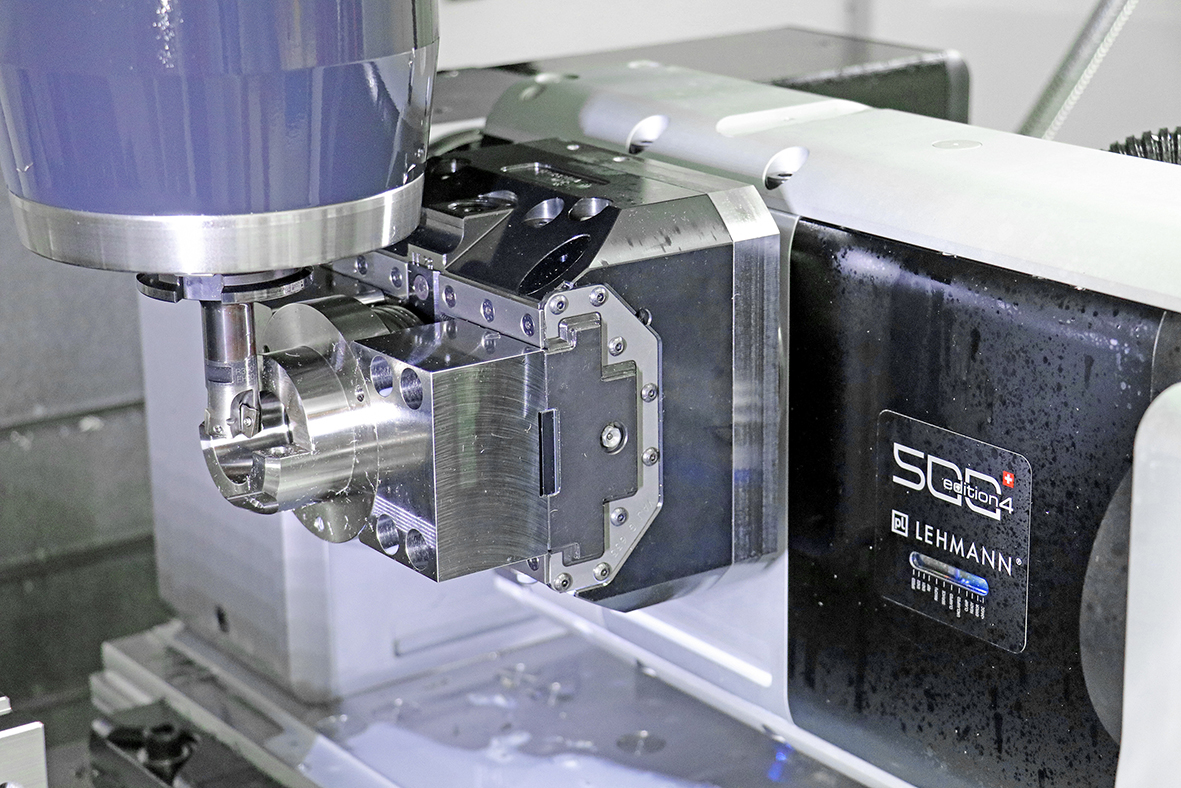

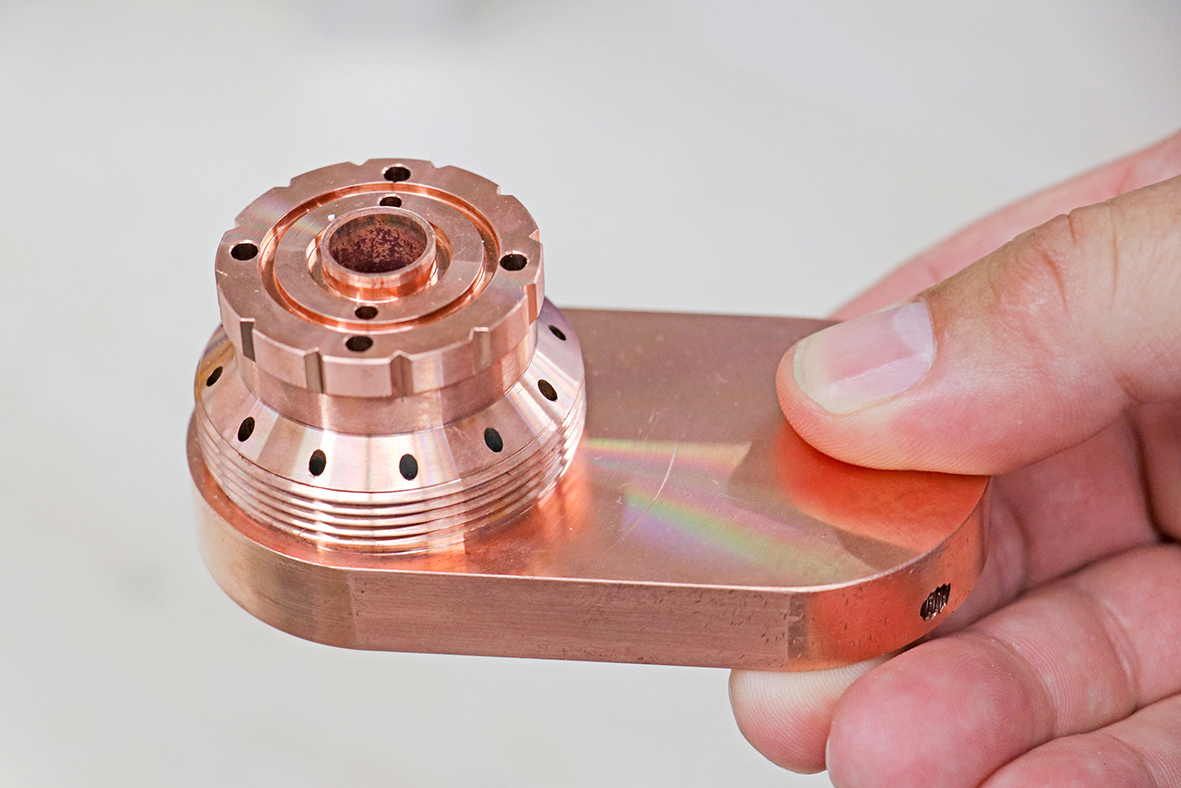

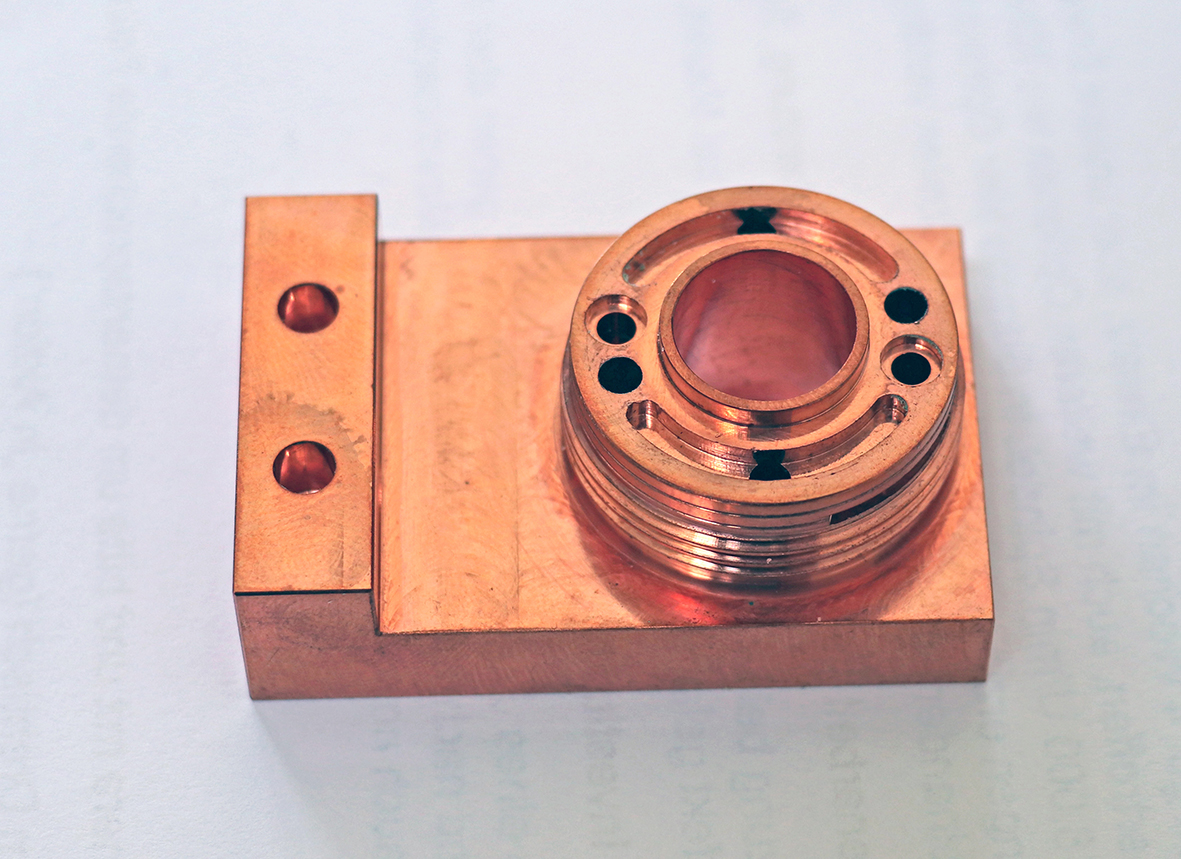

The two-axis LEHMANN rotary table T1-510520.RR TOP2 is 711 mm long, 301 mm wide and 250 mm high. It clamps workpieces of up to 340 mm in diameter. «That’s more than enough because we mainly process small to medium-sized workpieces up cube edge dimensions of about 150 mm,» explains Michael Loesch. A torsionally rigid overall system was a key requirement, so the decision was made for a clamped counterbearing. «Besides copper, brass, aluminum and bearing metals, we often process stainless steels which cannot be roughed without this option.» To this effect, clamping torques of max. 800 Nm in the 4th axis and up to 4’000 Nm in the 5th axis were a convincing feature.

Also, precision is a core value at LOESCH. The indexing accuracy Pa specified by pL LEHMANN of +/- 17 arc sec and +/- 21 arc sec (4th and 5th axis) as well as the average repeat accuracy Ps of +/- 2 arc sec, correspondingly, was verified by the metal-cutting experts on site using a calibration cube. The result even exceeded the specifications.

In practice, the high positioning speed of the rotary/tilting table is another great benefit. «If feasible, we use one single tool, e.g. a chamfer milling cutter, to execute all operations in sequence, rather turning and tilting the workpiece than repeatedly changing the tool.»

To Michael Loesch, programming with the Mazatrol SmoothG is another highlight: «In the past, 3+2 machines could only be programmed for 5-axis operation using G-Code – a tedious procedure if workpieces are complex. Now, we can use the Mazatrol programming system which I think is very user-friendly.» This needed some intensive up-front cooperation between pL LEHMANN and the Mazak control system developers, but the result was well worth the effort. «I can now program our VCN 530C with its two-axis rotary table just like a five-axis Mazak Variaxis. This reduces the programming effort to a fraction of the time.» Productivity gains immensely, particularly for single and small-series parts – production lots at LOESCH usually range between 20 and 200 pieces.

Michael Loesch is very satisfied with his investment: «Thanks to the Mazak VCN 530C and the two-axis rotary table from pL LEHMANN and the other options we specified, we have achieved significant time savings and reduced the effort required for re-clamping, thereby freeing up our machine operators to take care of other tasks.» With his next plans, the innovation-minded entrepreneur targets automation. In the future, the VCN shall be fed by a handling automat. The machine is already prepared accordingly. The pL LEHMANN rotary table offers media channels to facilitate the remote control of automatic clamping systems. «The force clamp on the rotary table is already pneumatically controlled, and the two vices on the machine table will then be converted from manual to hydro-pneumatic operation. This will allow us to fully machine all six sides without any manual intervention,» anticipates Michael Loesch. He is sure that such a machine concept is the future.

Innovative solutions for the industry

Specializing in precision engineering and optical systems, Loesch T-P-L Feinwerktechnik was founded by G. Adolf Loesch in 1950. The business, located in Darmstadt, is now run by his son Michael Loesch and has a workforce of ten, generating an annual turnover of around 2 million Euro. Loesch T-P-L (“Technische-Problem-Lösungen” – German for solutions solving technical problems) understands itself as an innovation partner of the industry. The services offered range from providing ideas to development assignments, design, production and assembly. Customers are supplied with individual components or assemblies, CE-approved, which are mostly used in measuring and testing equipment for the automotive industry and in the pharmaceutical and cosmetics industry. Core products are devices and components for plasma-powder and laser cladding, special parts for the chemical industry and mechatronical special-purpose machinery.

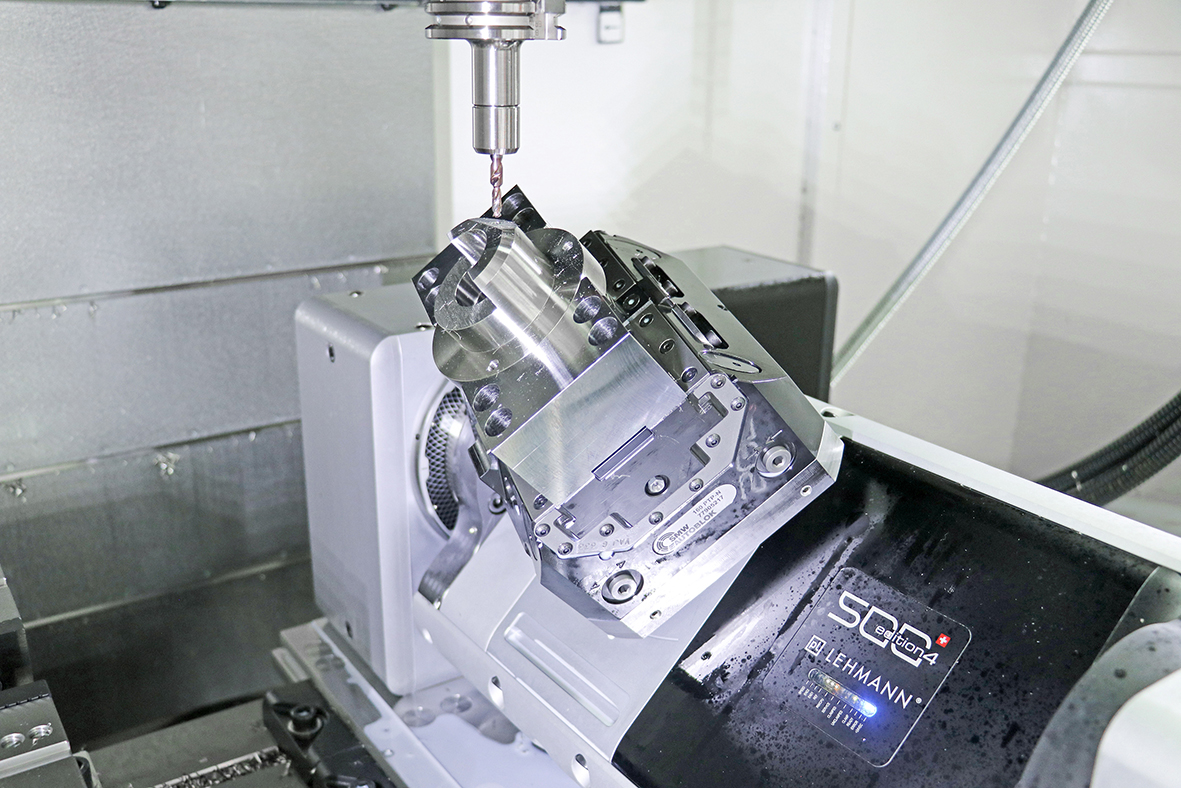

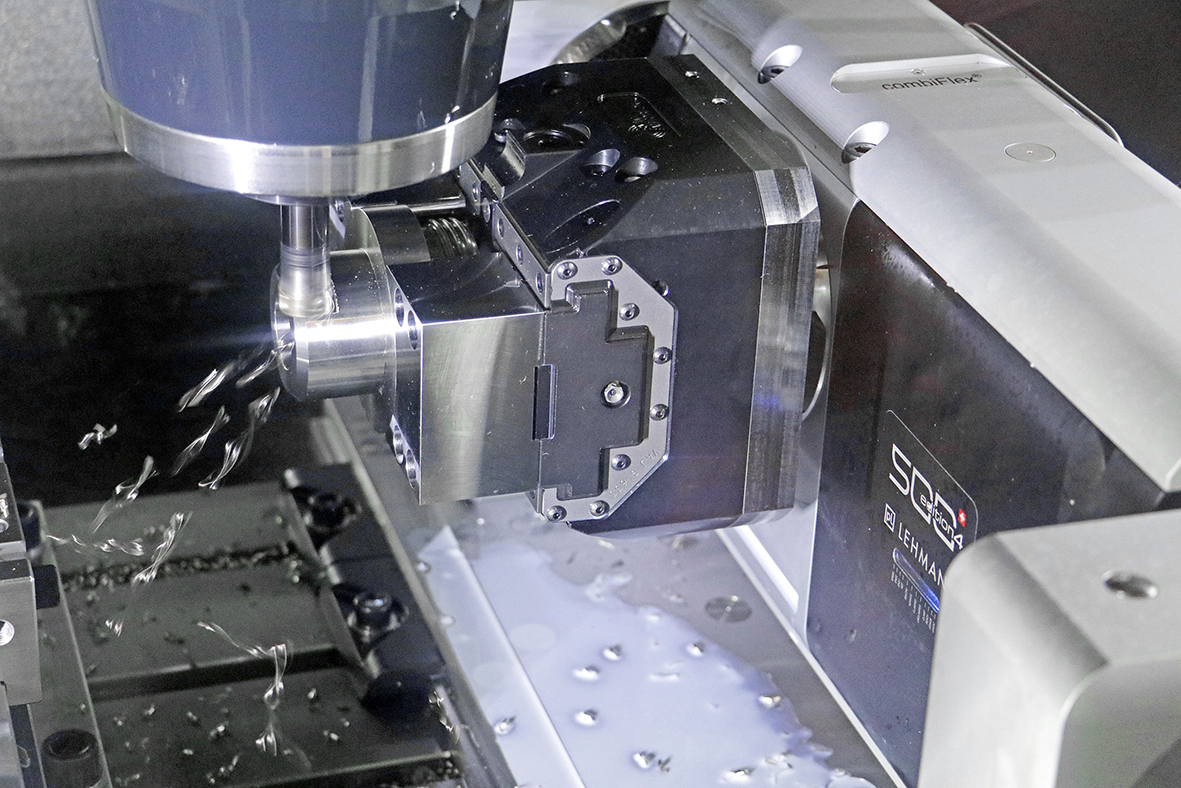

The pL LEHMANN T1-510520.RR TOP2 CNC rotary table turns the vertical three-axis Mazak VCN 530C milling machine into a five-axis machining center for the complete machining of complex parts. Images: pL LEHMANN

Machining of stainless steel parts is facilitated by the clamped counterbearing and high retention forces. In the past, LOESCH T-P-L needed 25 minutes to machine the part shown in the image; special clamping fixtures were required to realize angled bores and surfaces. The same part is now clamped only once and is fully machined within ten minutes.

Thanks to Mazak’s Mazatrol SmoothG control system, the VCN 530C three-axis machining center complemented by the CNC rotary table from pL LEHMANN is programmed very quickly and easily. G-Code programming is now only required for specific machining operations.

In addition to the rotating/tilting combination, the machine table also fits two 125 mm vices – ideal when changing from five-axis to three-axis mode for the machining of the sixth side.

Most delicate bores at different angles – no problem with the Mazak VCN 530C fitted with the two-axis rotary table from pL LEHMANN.

Nozzles of a plasma torch with angled bores in two axes with diameters ranging from 1 to 3 mm.

Bottom part of a plasma-powder torch.

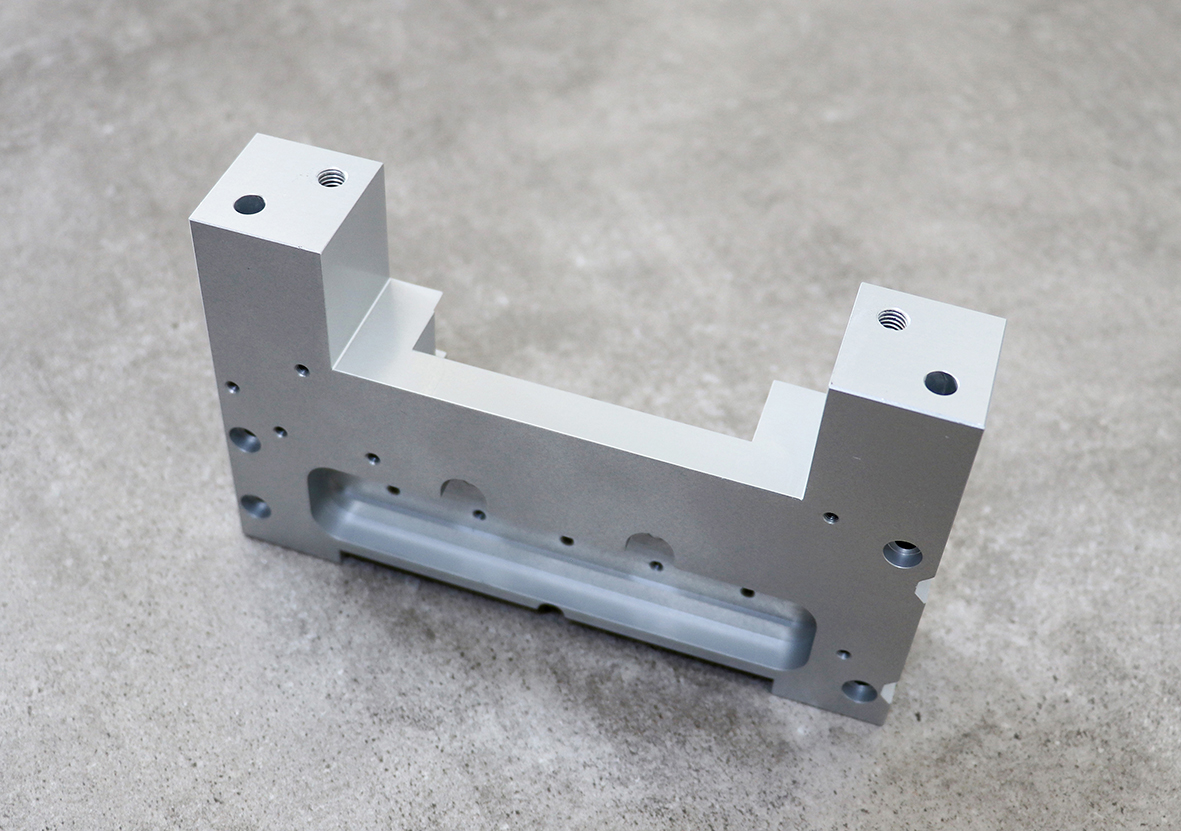

A three-axis part which however requires milling and drilling from six sides. Using a three-axis milling machine would require six clamping operations – and only two when using the Mazak VCN 530C with two-axis rotary table from pL LEHMANN.

Complex element of a testing device: It consists of a high number of milled parts which can now be machined at LOESCH T-P-L in five axes.

T1-510520 TOP2 rotary table from pL LEHMANN.

Contacts:

Peter Lehmann AG

Bäraustrasse 43

CH-3552 Bärau

Tel. +41 (0)34 409 66 66

Fax +41 (0)34 409 66 00

pls@plehmann.com

www.lehmann-rotary-tables.com

Loesch T-P-L mechatronic systems GmbH

Frankfurter Landstraße 70

D-64291 Darmstadt

Tel. +49 6151 87066-0

info@loesch-tpl.de

www.loesch-tpl.de