Mikron Switzerland AG, Agno Division Tool

Via Campagna 1

CH-6982 Agno

+41 91 610 40 00

+41 91 610 40 10

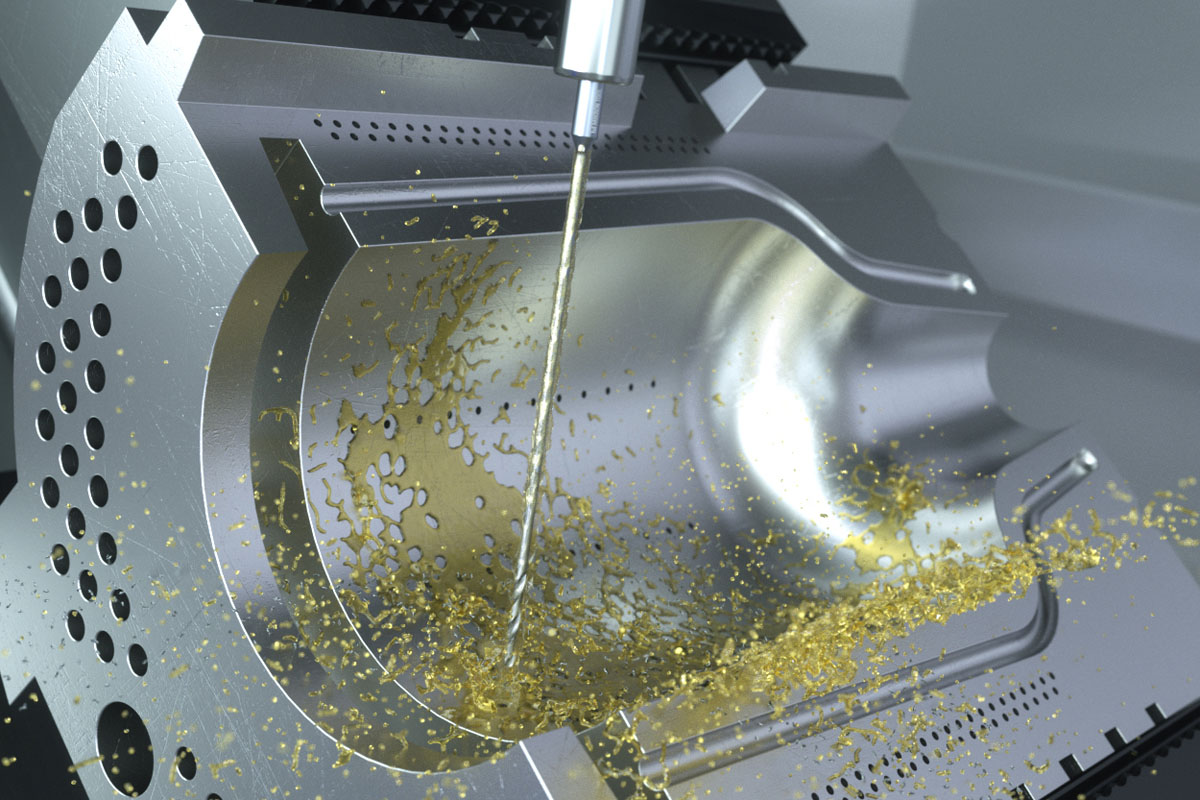

Small, precise and fast – Swiss Cutting Tools for Professionals

“Cutting tools are our passion, small dimensions are our speciality and hard to machine materials are our challenge”. Every single day at Mikron Tool is dedicated to achieving the best possible results in these areas.

Mission – Mikron Tool

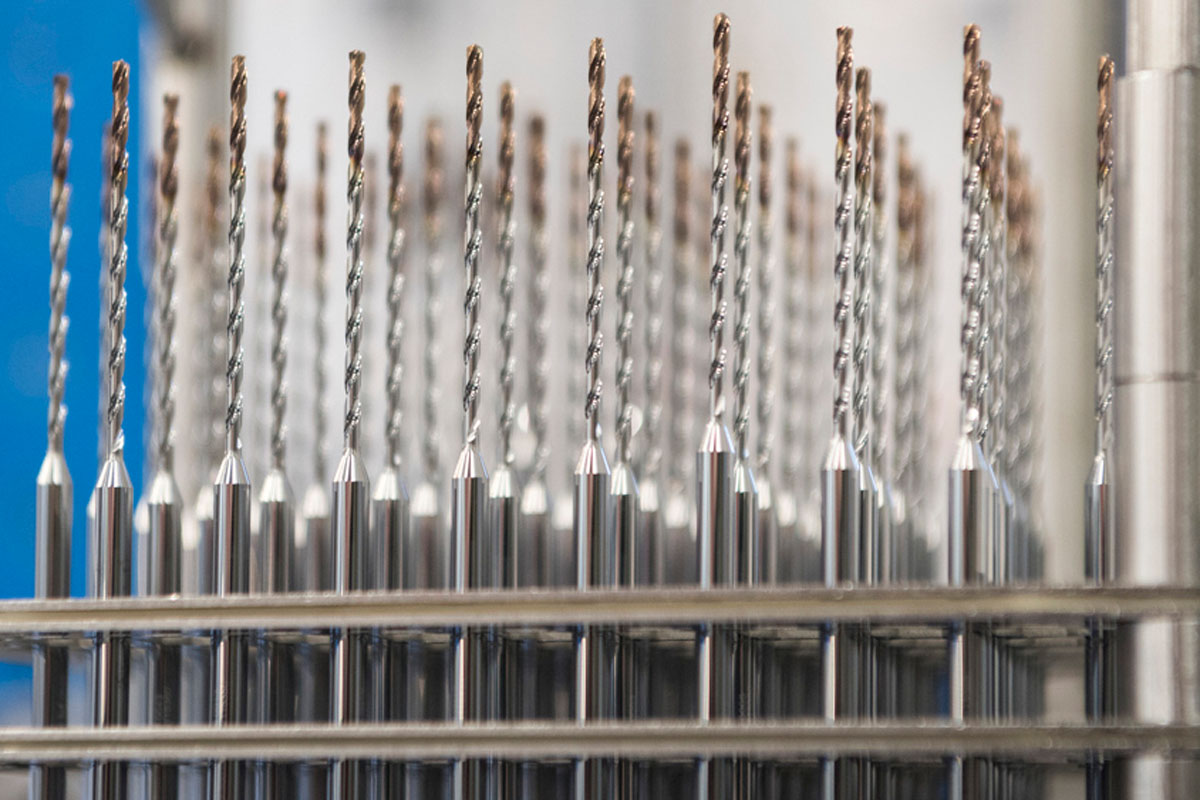

We are working daily to achieve a leading position worldwide in high precision machining of small dimensions and challenging materials. This includes the regular development of new and unique tools as well as customer specific solutions. In everything we undertake, a high level of competence is important. Focusing on our strong points is key to our success. Strong points such as well-trained and motivated employees, intensive development activities or investing in most advanced production technologies.

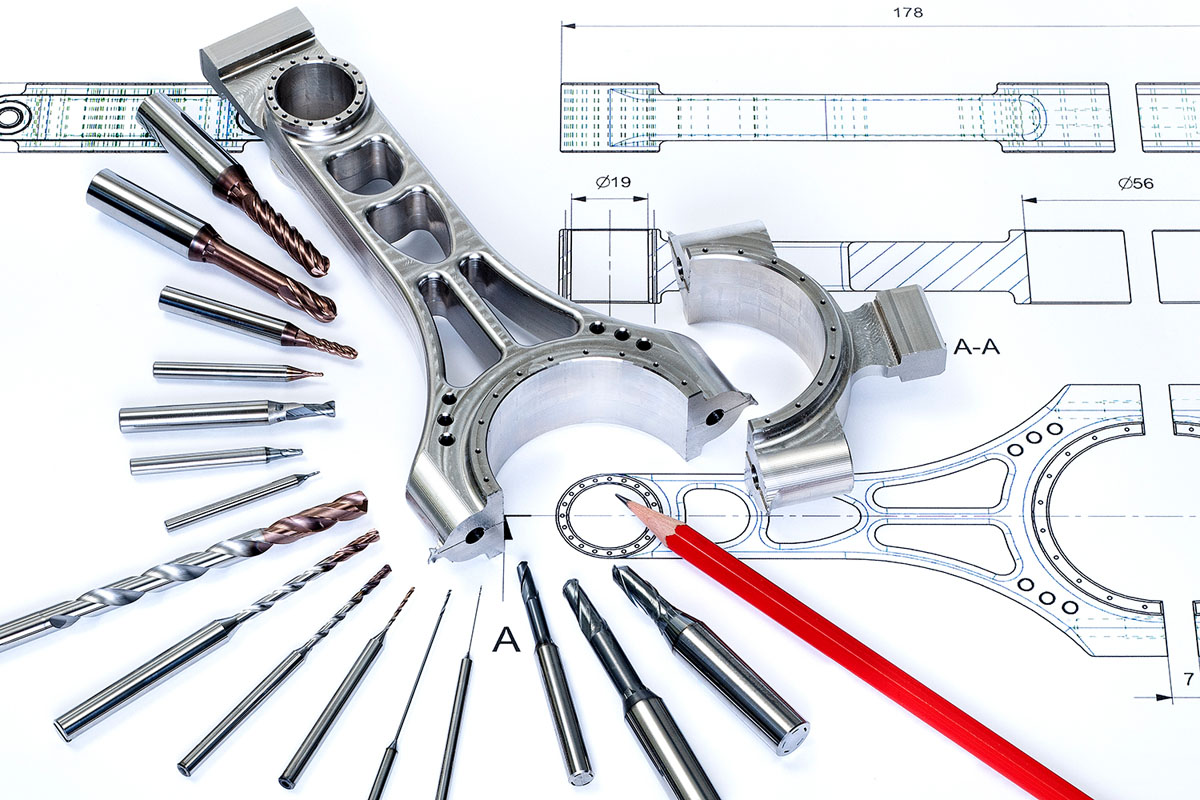

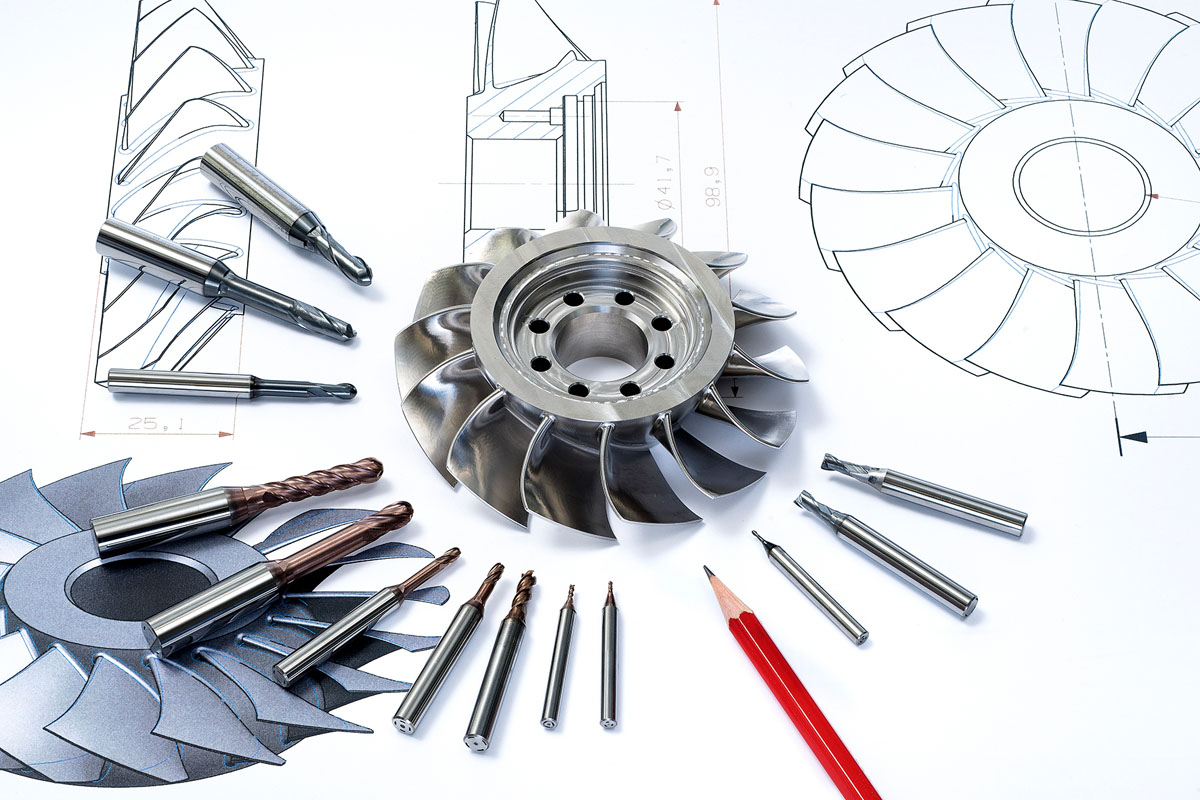

The tool range

Our strength lies in the development of carbide cutting tools for machining high-quality and biocompatible materials such as stainless steels, titanium, superalloys or CrCo alloys. We offer standardised tools for drilling, milling and deburring in a diameter range from 0.1 to 8 mm as well as customised solutions up to 32 mm for all machining operations.

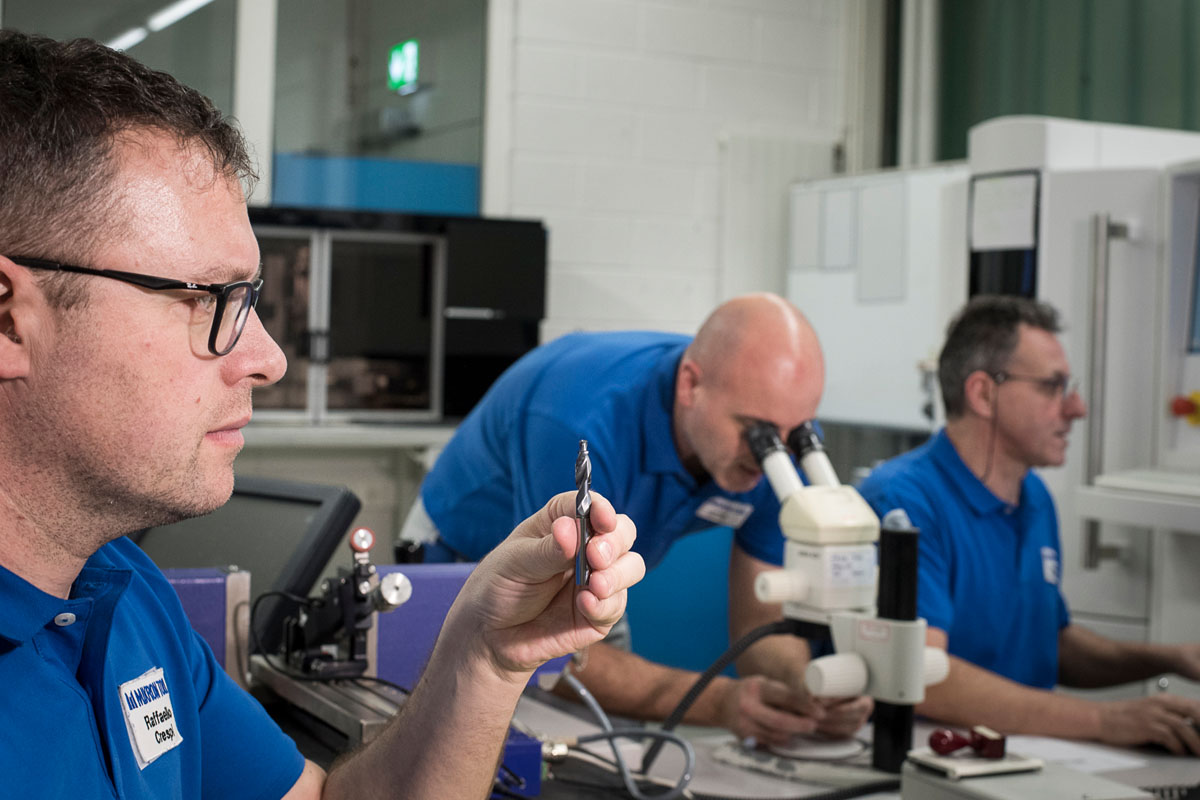

Technical support

How to produce a new part with the best adapted tools? What is the right tool for a new material? How to optimise quality and cycle time in an existing process? How to be more efficient and max out my possible cost saving? Shall I use standard tools or rely on a special solution with combined tools? To answer all these questions, we are at your disposal with our Technology Centre and our specialised cutting tool team!

A product is considered NEW at Mikron Tool only when it is unique and with high added value for the user. Without a doubt, this is true for every single CrazyLine product: The latest developments:

Deep holes in stainless steel

Up to 40xd in one shot, 4 times more through tool cooling capacity, these are the characteristics of the small drill CrazyDrill Cool SST-Inox. Due to internal coolant ducts, innovative geometry and coating, the machining of stainless steel, nickel based super alloys and CrCo-alloys has become simple and process stable. This goes for small diameters from 1mm to 6mm as well as deepbores up to 40 x d.

Tool concept for bone screws

CrazyTool Hexalobe is a new concept for machining hexalobular sockets on medical screws (better known as Torx® screws) made of stainless steel or titanium. A drilling and a milling tool are all you need to complete the four operations (pre- drilling – chamfering – milling – de- burring). In three steps you reduce the cycle time by 50% whilst achieving a highly precise profile and an excellent surface quality.

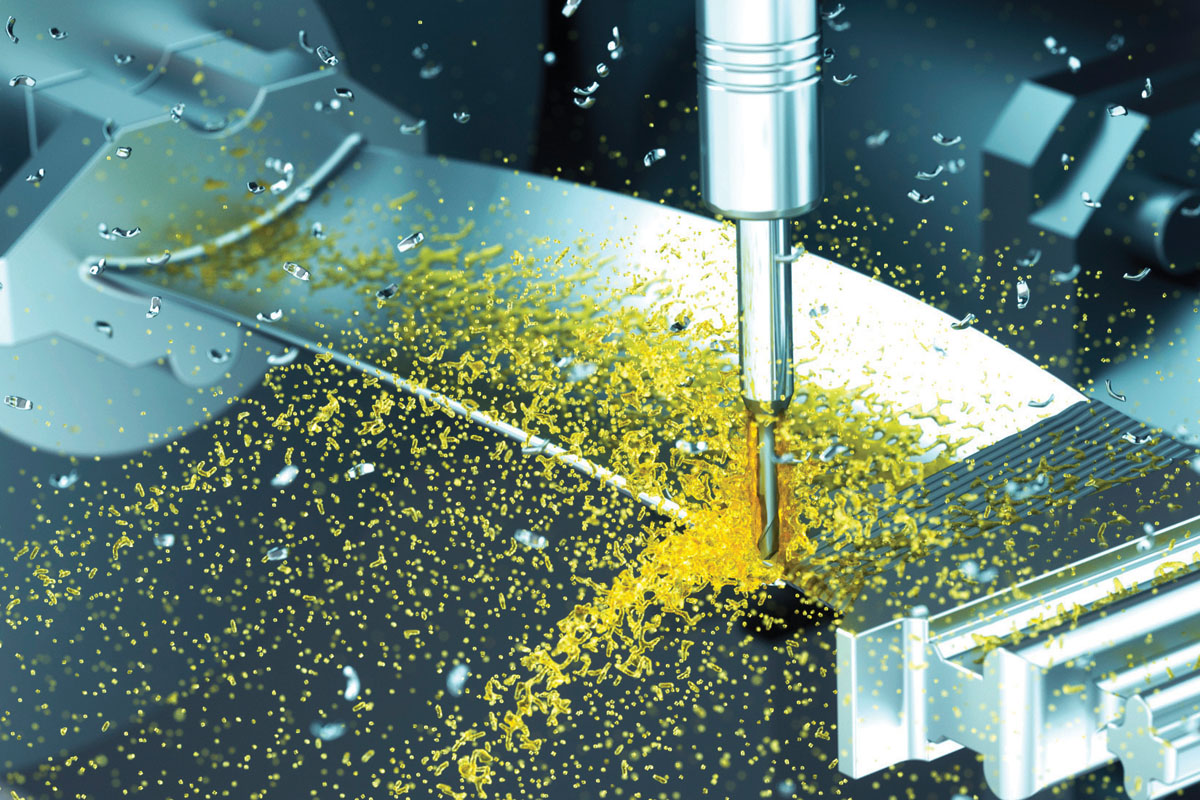

Milling in reduced spaces

With the new milling cutter CrazyMill Cool P&S it is now possible to plunge in all materials vertically (drilling) up to 1xd and continue horizontally with the milling of slots or pockets. This tool is available in diameters from 1 mm to 8 mm. Enlarged chip and flute space, stable cutting edges and integrated cooling channels guarantee a perfect chip control, avoid sticking and overheating of the material, increase tool life and contribute to highest cutting speeds and maximum performance.