Mikron Switzerland AG, Agno

Division Machining

Via Ginnasio 17

CH-6982 Agno

+41 91 610 61 11

+41 91 610 66 80

Mikron Machining

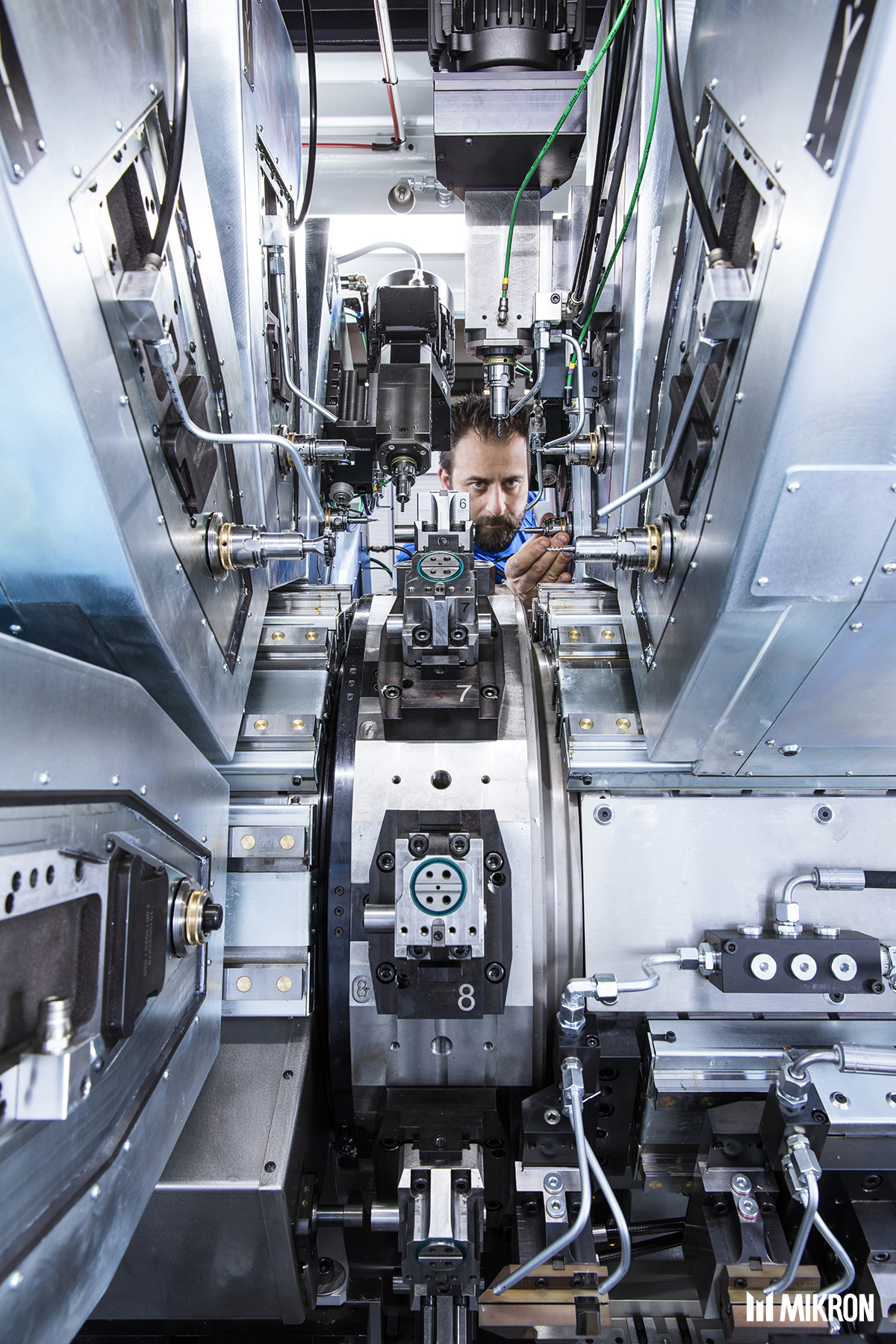

The Mikron Machining division is the leading supplier of customized, highly productive machining systems for the manufacturing of complex high-precision components made of metal such as turbocharger housings, injection nozzles and ballpoint pen tips. The Mikron Machining division employs around 475 people. Mikron Machining is headquartered in Agno (Switzerland). It also has sites in Agno (Switzerland), Rottweil (Germany), Monroe (USA) and Shanghai (China).

Website:

www.mikron.com/machining

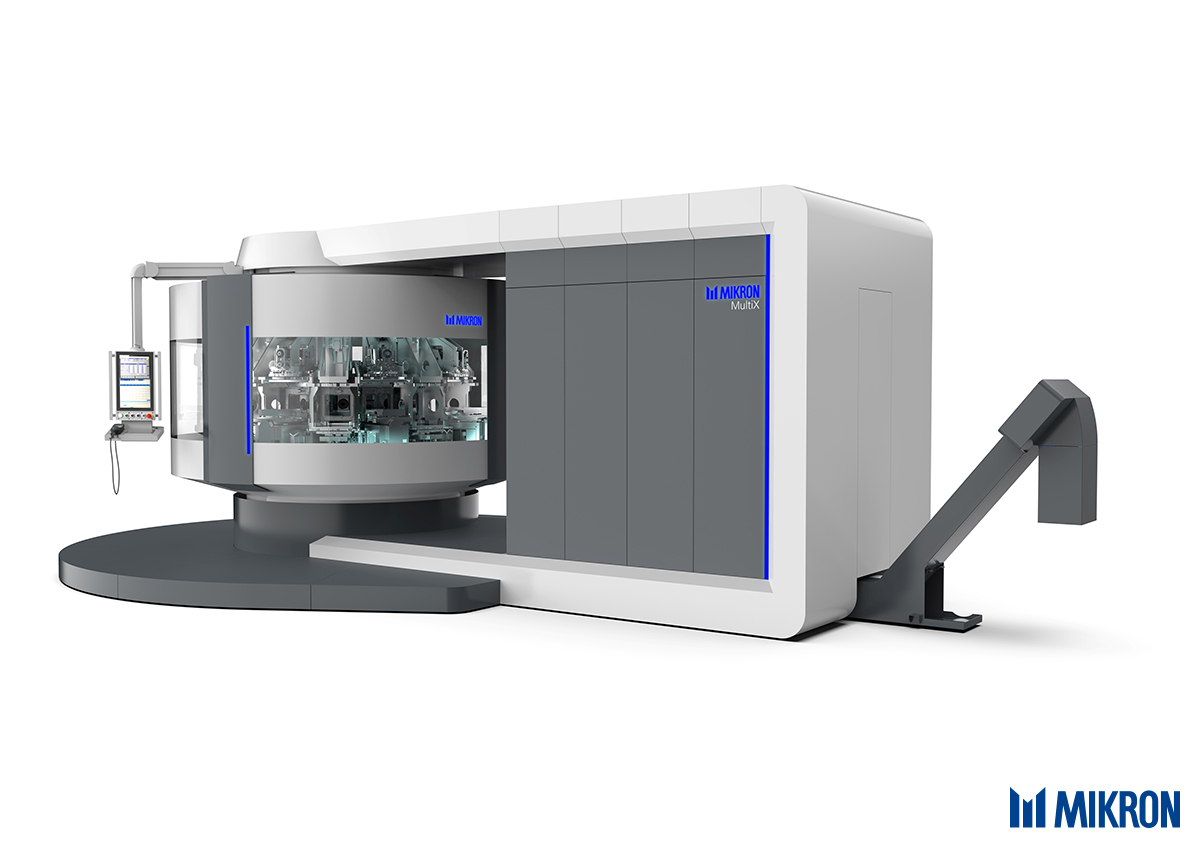

Mikron MultiX

New unrivalled possibilities – The platform for dedicated easy reconfigurable machining solutions for the production of 50 up to 5‘000‘000 parts.

Configured for your specific needs such as: productivity, precision, stiffness, reconfigurability, size, cost, power…Freely combine the platform elements and set up your machining solution.

www.mikron/multix

Videos Mikron MultiX:

https://www.youtube.com/playlist?list=PLKvqTbiHUYfKskZ1ELxexyTtIBtfiD-4S

Mikron miTool – The next level of tool monitoring

High precision and high-volume part production on Mikron high performance systems involve sophisticated machining processes.Advanced Tool monitoring becomes crucial to avoid unexpected machine downtime, machine breakage, tool damage, material scrap and the likely issues. Surface finish, tolerances and machine efficiency can be improved.

Mikron has been committed to better, more efficient machining for more than 100 years:

With the introduction of Mikron miTool – the next level in tool monitoring, we offer our customers finally a more powerful, easy way of tool monitoring with innovative features so you get the most out of your Mikron high performance system.

- WHAT MAKES Mikron miTool SO SPECIAL FOR YOU

- Highest sensibility and quality of data points deliver the finest and exact monitoring curves

- Intuitive icon driven graphical interface for easiest use and monitoring by operators

- Intelligent algorithm for advanced process optimization and cutting tool wear identification

- Mikron miTool is able to storage data and history for each tool configuration and monitoring curve

- Dashboard with statistical overview for each tool allows the optimization of the entire production process

- Mikron miTool permits all modifications (set up, regulations…) without machine stop

- Automatic actions programmable for each channel e.g. save data in database, send notification, preventively stop the machine

- Perfectly integrated into Mikron high performance systems

- Intelligent algorithm for defined and optimal intervals to change several cutting tools leads to higher machine efficiency

- Attractive pricing and fast return of invest